Solutions in India

Packaging Machinery Company in Chennai, India

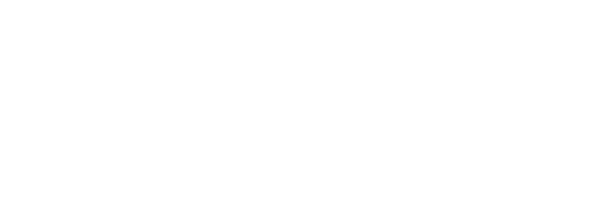

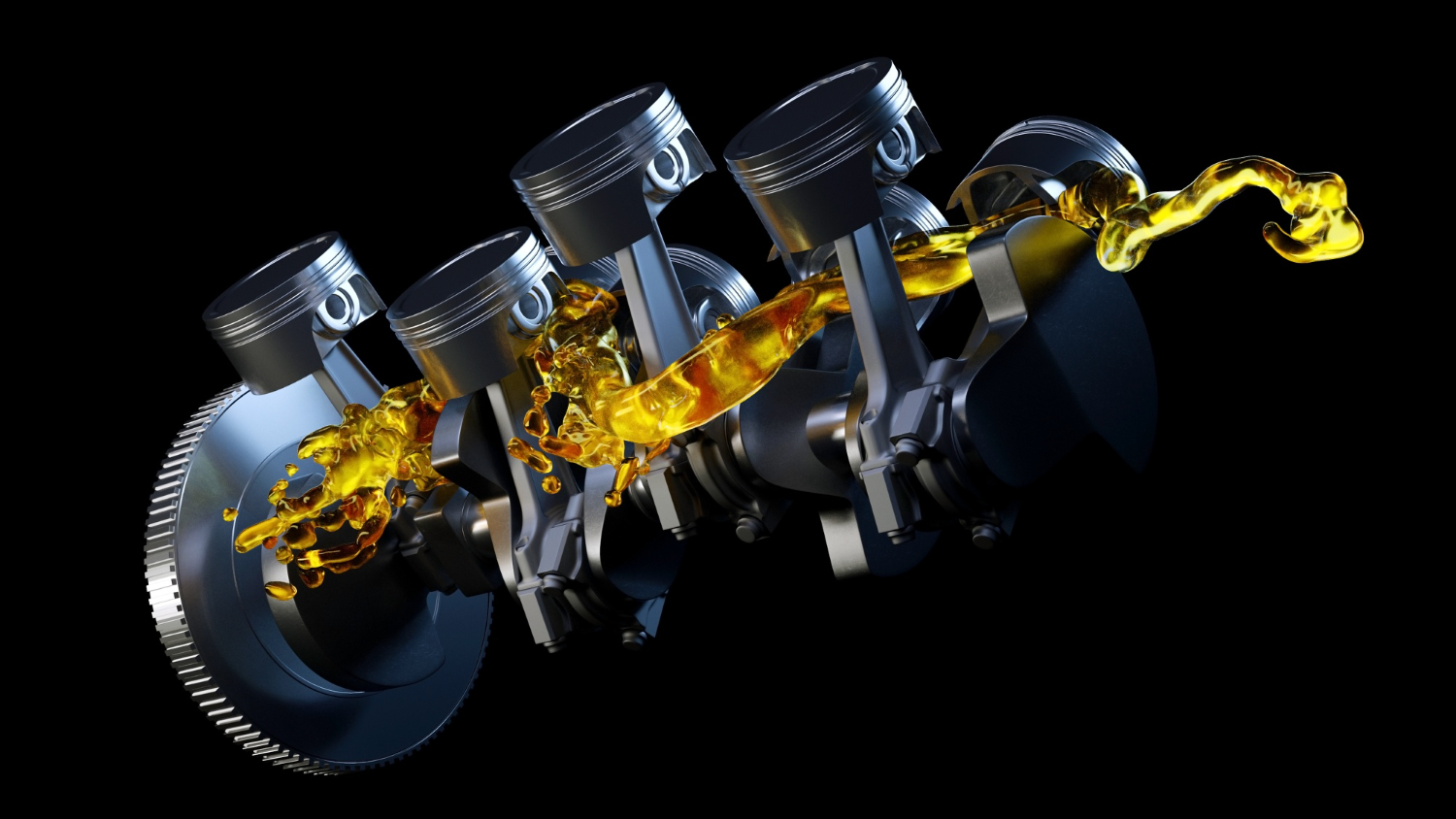

We are a leading packaging machinery company in Chennai, specializing in planning, designing, manufacturing, assembling, importing, exporting, and supplying cutting-edge packaging machinery across India and the world. With years of industry experience, we are committed to delivering high-quality, reliable, and efficient packaging machinery solutions and services for 25-plus industries, including oil, lube oil, chemicals, food, pharmaceuticals, cosmetics, and more.

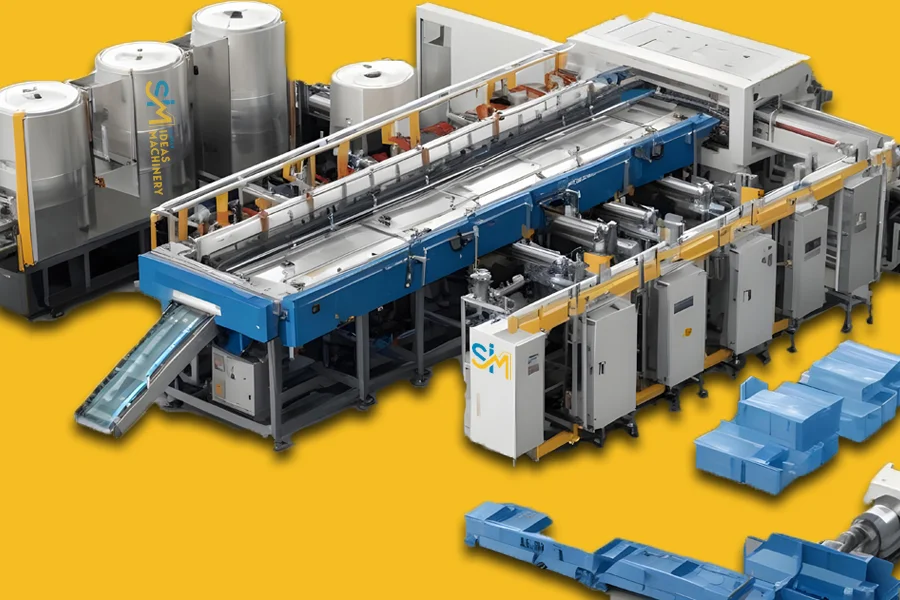

As a market leader in the manufacturing of Processing Machines, Filling Machines, Capping Machines, and Labelling Machines, we ensure that our products meet the highest standards of quality and performance. Our skilled team of engineers uses the latest technology to design and deliver custom-made solutions for every packaging need. We prioritize customer satisfaction, offering full support from installation to after-sales services. With a global presence and strong partnerships, we continue to lead the packaging machines industry by providing innovative and cost-effective solutions to businesses around the world.

Our Products

We are a premier packaging machine supplier based in Chennai (Madras), India, offering a wide range of innovative and efficient packaging solutions. Our diverse product range is engineered to optimize every stage of the production process, ensuring smooth workflows from processing and filling to capping, labelling, and sealing. Our machinery lineup is extensive, including case erectors, drop packers, robotic systems, case sealers, and strapping machines, all designed to streamline operations and boost productivity. With a strong commitment to reliability and precision, we help businesses achieve high-quality packaging while minimizing downtime and enhancing efficiency at every step.

Our Expertise

At Sankar Ideas, we excel in providing high-performance filling, capping, and labelling machines for a wide range of industries, including cooking oil, lubricant oil, and lub oil production. Our advanced machines are designed to ensure precision, efficiency, and reliability, catering to the specific needs of these sectors. Whether you're looking to optimize your packaging processes for food, beverage, pharmaceuticals, or industrial oils, our innovative solutions are built to enhance productivity. With a commitment to quality and innovation, Sankar Ideas helps you streamline operations and achieve seamless, high-quality packaging every time.

Which industry are you in?

At Sankar Ideas Packaging, with locations in Chennai and Ahmedabad, we serve a wide variety of industries by offering specialized packaging machinery designed to meet their specific requirements. Our equipment serves the Lubricant Industry, efficiently packaging various lubricants in multiple container sizes. In the Cosmetic & Perfume Industry, we deliver solutions for diverse cosmetic products. Our machinery is also designed for the Detergent Industry, ensuring adequate packaging of different detergent types. We support the Chemical Industry with equipment for safe chemical packaging and the Pharmaceutical Industry with solutions for drugs and supplements. Lastly, our machines are ideal for the Cooking Oil Industry, offering versatile packaging options.

Our Packaging Machine Services:

At Sankar Ideas

We provide a wide range of packaging machine services to meet all your needs, whether it’s a single machine, a complete production line, or ongoing maintenance.

New Machine Sales

We supply flexible packaging machines and equipment for bottles and containers. From production to end-of-line packaging, we provide everything you need, including creating, delivering, and installing the equipment.

Design of Production Lines

We help small and medium businesses design efficient production and packaging lines. Our process involves detailed discussions to ensure the final setup perfectly meets your needs.

Replacement Parts

If any machine part wears out, we can replace it for you. This can be part of our maintenance service or a one-time repair to keep your machines working smoothly.

Service Contracts

We offer maintenance contracts to extend the life of your packaging machines and ensure they run without problems. We have options for all budgets.

Spare Parts

We keep spare parts in stock for all the machines we supply, so if you ever need a replacement, we can quickly provide it.

Custom Solutions

We create custom production lines or adapt our equipment to fit into your current setup, ensuring everything works as you want it to.

Installation

Our skilled engineers will install the equipment in your factory and ensure it’s working perfectly. We’ll also train your team to use it with confidence.

Training

We provide training on all our machines so your team knows how to operate, maintain, and service them properly for long-lasting performance.

Packaging Machinery Manufacturer in Chennai, India

We are a leading packaging machinery manufacturer based in Chennai, India. We specialize in creating high-quality machines that help businesses streamline their packaging processes. With over 25 years of experience, our expertise lies in designing machines that make packaging faster, more efficient, and cost-effective. Our manufacturing facility is very well equipped with state-of-the-art technology and a skilled team, ensuring each machine is built to meet industry standards and customer needs.

Our facility is designed to handle every step of the manufacturing process, from design and assembly to quality testing. We use advanced equipment to produce reliable machines, such as filling, labelling, capping, and sealing machines. Each product is very carefully tested to ensure it operates very smoothly and efficiently, minimizing downtime and maximizing productivity for our customers. By offering tailor-made solutions, we help businesses of all sizes improve their packaging operations and achieve tremendous success.

The Ultimate Guide to Selecting the Right Packaging Machinery for Optimal Production Efficiency?

Choosing the right packaging machinery is a critical decision for any production business. The right equipment can enhance productivity, reduce downtime, and support long-term growth. This guide covers the eight essential factors to consider when investing in packaging machinery, including production speed, product compatibility, flexibility, maintenance needs, quality, safety standards, and after-sales support. By evaluating these essential aspects, business owners can select the most suitable machinery to meet their unique production requirements and operational goals.

Production Speed and Capacity

Ensure the machine can handle your production volume efficiently. Consider your current output and any anticipated growth so the machinery can accommodate increasing demands without sacrificing quality.

Type of Product

Different machines are designed for various product types, such as liquid, solid, or semi-solid. Make sure the machinery is suitable for the consistency, fragility, and packaging style required by your product.

Compatibility with Packaging Material

The machine must be compatible with the materials you plan to use, such as glass, plastic, cardboard, or metal. Some machines may be optimized for certain materials, impacting performance and durability.

Flexibility and Adaptability

Look for machinery that can handle multiple packaging styles or sizes. This flexibility is valuable if you need to adapt to changing market demands or expand your product line.

Ease of Operation and Maintenance

Choose an equipment system that is easy for your team to operate and maintain, reducing downtime. Simple maintenance requirements can save costs and prolong the machine’s lifespan.

Quality and Reliability

Invest in machines from reputable manufacturers known for durability and reliability. High-quality machinery may have a higher upfront cost but can reduce long-term repair and replacement expenses.

Safety and Compliance

Ensure the machinery meets industry safety standards and complies with relevant regulations. This is essential for protecting your workers and avoiding legal issues.

After-Sales Support and Availability of Spare Parts

Choose a supplier who provides good after-sales support, including training, prompt maintenance services, and readily available genuine spare parts. This will maintain smooth production flow and minimize the chances of unexpected downtime.

Delighted Customers Share Their Experiences with Sankar Ideas Machinery!

Frequently Asked Questions (FAQ)

We provide a wide range of leading packaging machinery, including automatic and semi-automatic packaging machines for filling, sealing, labelling, wrapping, cartooning, and palletizing, designed to meet various industry needs, such as food, beverage, oil, lube oil, pharmaceuticals, and cosmetics.

Yes, we customize solutions tailored to your product's size, shape, and packaging requirements. Whether you need liquid, oil, powder, granular, or solid product packaging, we can design and build machinery to suit your needs.

Our machines are designed for ease of use, with user-friendly interfaces and automated features. Additionally, we provide training and comprehensive manuals for your staff. Routine maintenance is straightforward, and our support team is always available for assistance.

Yes, we offer complete installation, testing, and commissioning services to ensure that your new machinery is appropriately set up and ready to run efficiently in your production line.

Delivery times vary depending on the project complexity and customization of the machinery. Standard machines typically ship within 4 weeks, while customized machinery may take longer. During the consultation, we will provide you with an estimated lead time.

We provide a warranty on all our machines, covering defects in materials and artistry. We also offer extended service contracts for ongoing maintenance and support after the warranty period.

Yes, our packaging machines can be easily integrated into your existing production line. Our team will assess your current product line setup and design solutions to ensure seamless integration without disrupting your workflow.

We offer both on-site and remote support, as well as preventative maintenance services to keep your machines running smoothly. Our customer support team is available to help with troubleshooting, repairs, and spare parts supply.

Our machines are compatible with a variety of packaging materials, including plastic, glass, paper, aluminium, and flexible films. Based on your particular requirements, we can advise on the best materials for your product.

The cost of our packaging machinery depends on factors like the type of machine, customization options, production capacity, and the complexity of your packaging requirements. We offer exceptionally, very competitive rates and provide a detailed quotation after discussing your needs and wants.